Developing a Framework for Effective Air Quality Management

3.7 Implementation of Air Quality Plans

3.7.2 Rule Development Programs

3.7.2.1 Keys to Developing Effective Rules

The enforcement element of air quality management falls nicely into two general activities. First, rules and/or regulations must be written around which compliance activities are based; and second, steps must be taken to ensure that adopted rules are followed by the affected entities. In the best cases, rules are written based upon air quality plans that have considered the relevant air quality problems and balanced the emission reduction priorities. This approach makes the rule development part of the process more transparent to the affected industries and to the public in general. However, there are many cases where rules are adopted independently of any plans based on obvious emissions or international norms.

As noted in the previous paragraph the adoption of rules based on a comprehensive air quality plan is the best option; however, there are times when needed controls are so obvious that actions are appropriate in the absence of a plan. In either case, the adopted rules must be designed with four criteria in mind:

1. Control Appropriateness: Emission reduction needs of the region (or nationally and internationally), including the amount of reductions committed to in the AQMP

2. Cost Effectiveness: How much implementation of the rule will cost compared to the emissions reductions to be achieved

3. Affordability: The ability of the affected industry to absorb the cost of implementation. In some instances the control may be cost effective in terms of pollutant reduced but the industry may not be able to absorb the cost of the controls, if the industry has a low profit margin or some other reason. Subsidies, loans, or passing the cost onto the consumer may be an option to bolster the affordability in this case. Care must be taken in applying this criteria since business often claim economic impacts that are not real or highly exaggerated.

4. Ease of Implementation: Ability of the industry to implement the rule (time frames, cost, etc.)

5. Enforceability: Ability of the governmental units to enforce the rule

While it may seem like a mantra, emission reduction needs are best assessed through a comprehensive regional air quality management plan. However, if no such plan is available, then national or international standards of control may be used in lieu of a plan while an air quality management process is brought into operation. For example, in the United States, all emission sources in polluted areas are required to adopt what is termed as Reasonably Available Control Technology (RACT). Even in areas that meet air quality standards, most States and local air quality programs require RACT. In the absence of an air quality plan it is difficult to know if RACT is adequate for a region. Of course, the affected parties are not typically happy to spend money in the absence of an obvious air quality problem, but it has become a norm to expect a “reasonable” level of control in almost any situation.

In non-attainment areas in the United States, all major existing sources must attain a higher level of control called Best Available Control Technology (BACT) and new sources must meet criteria designated as Lowest Achievable Emission Rate (LAER). Los Angeles has taken the control requirements one step further and requires BACT on all sources that emit 10 tons or more of any pollutant in a year.

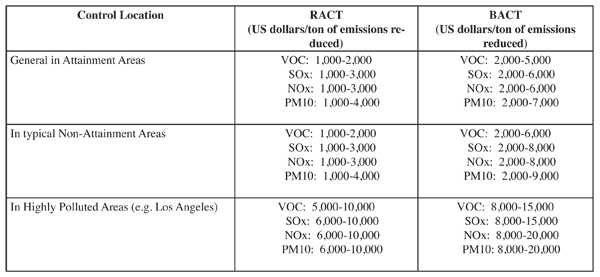

In practice, it is often difficult to tell the difference between BACT and LAER. RACT and BACT are typically differentiated from one another by the cost of the control options, which is referred to as Cost Effectiveness. The Cost Effectiveness of a rule is typically defined in terms of industry implementation cost per ton of emissions reduced. The cost analysis for an industry includes both capital equipment cost and operational cost prorated over a fifteen or twenty year period. There are no specific guidelines as to the cost effectiveness to use, but the U.S. EPA, State air quality programs, and Local air quality programs have tended to coalesce around general values. Table 3.7.2-1 indicates typical cost effectiveness rates applied in the United States. The ranges in the table reflect both regional variations and industry type variations. Small businesses are typically not held to as high a cost effectiveness ratio as large businesses.

The U.S. EPA also maintains a RACT/BACT/LAER Clearing house (http://cfpub1.epa.gov/rblc/htm/bl02.cfm) in order to help air quality agencies in the U.S. to define appropriate control technologies and to maintain consistency around the country.

In South America, the rule development processes are not as well defined at this writing as in the United States so a clear pattern of cost effectiveness values is not available. One also does not see cost effectiveness come up as much in European rules as well. As discussed earlier, the negotiated rulemaking approach used more often in Europe does not seem to necessitate so much cost and/or benefit analysis. Controls chosen in South America tend to reflect those in the middle row of 3.7.2-1. Once coal and wood burning was eliminated from general use in London and elsewhere in Europe, the air pollution problems have generally been less severe than seen in many other parts of the world. This is due to better atmospheric mixing, lower temperatures and less sunlight, and a better transportation infrastructure than in much of the rest of the world. However, Europeans have typically adopted controls that parallel those in the United States and the cost effectiveness of their controls fall between the second and third rows of 3.7.2-1. In researching control options for Los Angeles, it has sometimes been found that some areas in Europe, notably the Scandinavian countries, have adopted even more stringent regulations than in the U.S. even in the absence of severe air pollution problems.

It might seem unusual for areas in the U.S., Europe, and elsewhere impose controls on sources in areas where air quality meets health standards and should continue to do so. These control decisions appear to be driven by three considerations. First, the health impacts due to air pollution are not perfectly understood and there is concern about even coming close to the standards. Health standards have been regularly made more stringent as more information is accumulated. In the U.S. and Europe, air quality is classified as poor if it is more than halfway between background levels and the air quality standard for that pollutant. A second issue is that there has been concern that industry will flee to locations with lower control levels and use this argument as a way to blackmail urban areas into minimizing regulations to keep the jobs. Thus, in the U.S. all new major sources are required by federal law to use BACT no matter where they locate. Third, while health is the major concern with respect to air pollution, there is also a desire to prevent non-health related air pollution impacts such as deteriorated visibility and acid deposition and to minimize impacts on plant and animal life. Since tourism is an important aspect of many economies, the concern that tourists might turn to more natural less polluted areas for travel is a major concern.

3.7.2.2 The Steps Associated with the Rule Development Process

A successful rule making process typically follows five stages of development.

* First –Scoping Analysis: An emission source to be controlled is identified by the regulatory agency and is reviewed. A first cut estimate of the amount and variety of affected sources and the overall emissions it produces is estimated.

* Second- Workgroup Formation & Data Gathering: A workgroup is formed to review emission points and control options and to advise government staff as to control options and implementation issues. The workgroup usually contains government staff, impacted industries, and public members and meets monthly or weekly in some cases. The working group looks closely at the industry and sources effected and sometimes gathers additional information from the affected industry, in terms of times and amounts of operation, costs, and number of facilities. The group evaluates existing or potential control options, including identifying BACT, RACT, and other effective technologies, and develops estimates of cost effectiveness. The regulatory agency staff typically does most of the analysis and presents to the group for debate.

* Third- Proposed Draft Rule: In light of the information gathered in the second step as well as commitments outlined in the AQMP, a draft rule is produced and circulated for up to ninety days and comments can be received.

* Forth- Proposed Final Rule: Staff modifies the rule if warranted based on comments and submits the rule to the adopting authority. The adopting authority varies from location to location and can be a single person in the case of the U.S. EPA or a public board as is the case of Los Angeles, California.

* Fifth- Rule Adoption: A public hearing may be held. Typically, a hearing is required before adoption of any rule with a thirty day notice, and the rule adoption must be done at a public meeting. For the U.S. EPA, regulations must be submitted to the Office of Management of the Budget and approval received before approval by the Administrator of the U.S. EPA. Once the rule is adopted through this process, the rule can then be implemented and enforced.

Most often, a successful proposed rule will contain the following elements:

* Specific definition of sources to be affected

* Emissions or control efficiency limits to meet, with specific timelines of when the limit will take effect

* Examples of technology or operations that will be required to meet emissions limits

* Explicit list of any exceptions

* Testing Protocol or Specifics of how to perform necessary compliance tests

* Record keeping and reporting requirements

* Penalties for non-compliance

* A summary of the compliance cost (affordability analysis of cost of implementation of the industry as well as cost effectiveness in terms of $/ton pollutant reduced)

* Estimated socioeconomic impacts to the industry being affected

* Estimated emissions reduction and health benefits resulting from rule implementation

* Comparison of rule with AQMP or other plan commitments

* Discussion of other effects, such as water pollution, global warming gases, etc.

* Documentation and references to all studies, data, and workgroup minutes.

In addition to cost, the adopting agency must also consider the lead times that are to be imposed for rule implementation. The lead time allowed before a rule comes into effect is determined based on two criteria. First, the availability of needed technology must be considered and the time that it will require for a source to implement the technology. Second, the ability of the industry to absorb the cost of implementing the control requirements must be considered. In most locations, rules requiring basic off-the-shelf technology with costs that are small relative to the size of the operation typically expect implementation within a year or two at the most. In cases where the control technology is just being developed or becoming available and/or the costs are significant relative to the size of the regulated source, then three to ten years are allowed to implement a control regulation. Natural maintenance cycles at industrial sources can also be considered in establishing rule deadlines if it does not push the deadlines into unreasonable timeframes.

The enforcement element of air quality management falls nicely into two general activities. First, rules and/or regulations must be written around which compliance activities are based; and second, steps must be taken to ensure that adopted rules are followed by the affected entities. In the best cases, rules are written based upon air quality plans that have considered the relevant air quality problems and balanced the emission reduction priorities. This approach makes the rule development part of the process more transparent to the affected industries and to the public in general. However, there are many cases where rules are adopted independently of any plans based on obvious emissions or international norms.

As noted in the previous paragraph the adoption of rules based on a comprehensive air quality plan is the best option; however, there are times when needed controls are so obvious that actions are appropriate in the absence of a plan. In either case, the adopted rules must be designed with four criteria in mind:

1. Control Appropriateness: Emission reduction needs of the region (or nationally and internationally), including the amount of reductions committed to in the AQMP

2. Cost Effectiveness: How much implementation of the rule will cost compared to the emissions reductions to be achieved

3. Affordability: The ability of the affected industry to absorb the cost of implementation. In some instances the control may be cost effective in terms of pollutant reduced but the industry may not be able to absorb the cost of the controls, if the industry has a low profit margin or some other reason. Subsidies, loans, or passing the cost onto the consumer may be an option to bolster the affordability in this case. Care must be taken in applying this criteria since business often claim economic impacts that are not real or highly exaggerated.

4. Ease of Implementation: Ability of the industry to implement the rule (time frames, cost, etc.)

5. Enforceability: Ability of the governmental units to enforce the rule

While it may seem like a mantra, emission reduction needs are best assessed through a comprehensive regional air quality management plan. However, if no such plan is available, then national or international standards of control may be used in lieu of a plan while an air quality management process is brought into operation. For example, in the United States, all emission sources in polluted areas are required to adopt what is termed as Reasonably Available Control Technology (RACT). Even in areas that meet air quality standards, most States and local air quality programs require RACT. In the absence of an air quality plan it is difficult to know if RACT is adequate for a region. Of course, the affected parties are not typically happy to spend money in the absence of an obvious air quality problem, but it has become a norm to expect a “reasonable” level of control in almost any situation.

In non-attainment areas in the United States, all major existing sources must attain a higher level of control called Best Available Control Technology (BACT) and new sources must meet criteria designated as Lowest Achievable Emission Rate (LAER). Los Angeles has taken the control requirements one step further and requires BACT on all sources that emit 10 tons or more of any pollutant in a year.

In practice, it is often difficult to tell the difference between BACT and LAER. RACT and BACT are typically differentiated from one another by the cost of the control options, which is referred to as Cost Effectiveness. The Cost Effectiveness of a rule is typically defined in terms of industry implementation cost per ton of emissions reduced. The cost analysis for an industry includes both capital equipment cost and operational cost prorated over a fifteen or twenty year period. There are no specific guidelines as to the cost effectiveness to use, but the U.S. EPA, State air quality programs, and Local air quality programs have tended to coalesce around general values. Table 3.7.2-1 indicates typical cost effectiveness rates applied in the United States. The ranges in the table reflect both regional variations and industry type variations. Small businesses are typically not held to as high a cost effectiveness ratio as large businesses.

The U.S. EPA also maintains a RACT/BACT/LAER Clearing house (http://cfpub1.epa.gov/rblc/htm/bl02.cfm) in order to help air quality agencies in the U.S. to define appropriate control technologies and to maintain consistency around the country.

In South America, the rule development processes are not as well defined at this writing as in the United States so a clear pattern of cost effectiveness values is not available. One also does not see cost effectiveness come up as much in European rules as well. As discussed earlier, the negotiated rulemaking approach used more often in Europe does not seem to necessitate so much cost and/or benefit analysis. Controls chosen in South America tend to reflect those in the middle row of 3.7.2-1. Once coal and wood burning was eliminated from general use in London and elsewhere in Europe, the air pollution problems have generally been less severe than seen in many other parts of the world. This is due to better atmospheric mixing, lower temperatures and less sunlight, and a better transportation infrastructure than in much of the rest of the world. However, Europeans have typically adopted controls that parallel those in the United States and the cost effectiveness of their controls fall between the second and third rows of 3.7.2-1. In researching control options for Los Angeles, it has sometimes been found that some areas in Europe, notably the Scandinavian countries, have adopted even more stringent regulations than in the U.S. even in the absence of severe air pollution problems.

It might seem unusual for areas in the U.S., Europe, and elsewhere impose controls on sources in areas where air quality meets health standards and should continue to do so. These control decisions appear to be driven by three considerations. First, the health impacts due to air pollution are not perfectly understood and there is concern about even coming close to the standards. Health standards have been regularly made more stringent as more information is accumulated. In the U.S. and Europe, air quality is classified as poor if it is more than halfway between background levels and the air quality standard for that pollutant. A second issue is that there has been concern that industry will flee to locations with lower control levels and use this argument as a way to blackmail urban areas into minimizing regulations to keep the jobs. Thus, in the U.S. all new major sources are required by federal law to use BACT no matter where they locate. Third, while health is the major concern with respect to air pollution, there is also a desire to prevent non-health related air pollution impacts such as deteriorated visibility and acid deposition and to minimize impacts on plant and animal life. Since tourism is an important aspect of many economies, the concern that tourists might turn to more natural less polluted areas for travel is a major concern.

3.7.2.2 The Steps Associated with the Rule Development Process

A successful rule making process typically follows five stages of development.

* First –Scoping Analysis: An emission source to be controlled is identified by the regulatory agency and is reviewed. A first cut estimate of the amount and variety of affected sources and the overall emissions it produces is estimated.

* Second- Workgroup Formation & Data Gathering: A workgroup is formed to review emission points and control options and to advise government staff as to control options and implementation issues. The workgroup usually contains government staff, impacted industries, and public members and meets monthly or weekly in some cases. The working group looks closely at the industry and sources effected and sometimes gathers additional information from the affected industry, in terms of times and amounts of operation, costs, and number of facilities. The group evaluates existing or potential control options, including identifying BACT, RACT, and other effective technologies, and develops estimates of cost effectiveness. The regulatory agency staff typically does most of the analysis and presents to the group for debate.

* Third- Proposed Draft Rule: In light of the information gathered in the second step as well as commitments outlined in the AQMP, a draft rule is produced and circulated for up to ninety days and comments can be received.

* Forth- Proposed Final Rule: Staff modifies the rule if warranted based on comments and submits the rule to the adopting authority. The adopting authority varies from location to location and can be a single person in the case of the U.S. EPA or a public board as is the case of Los Angeles, California.

* Fifth- Rule Adoption: A public hearing may be held. Typically, a hearing is required before adoption of any rule with a thirty day notice, and the rule adoption must be done at a public meeting. For the U.S. EPA, regulations must be submitted to the Office of Management of the Budget and approval received before approval by the Administrator of the U.S. EPA. Once the rule is adopted through this process, the rule can then be implemented and enforced.

Most often, a successful proposed rule will contain the following elements:

* Specific definition of sources to be affected

* Emissions or control efficiency limits to meet, with specific timelines of when the limit will take effect

* Examples of technology or operations that will be required to meet emissions limits

* Explicit list of any exceptions

* Testing Protocol or Specifics of how to perform necessary compliance tests

* Record keeping and reporting requirements

* Penalties for non-compliance

* A summary of the compliance cost (affordability analysis of cost of implementation of the industry as well as cost effectiveness in terms of $/ton pollutant reduced)

* Estimated socioeconomic impacts to the industry being affected

* Estimated emissions reduction and health benefits resulting from rule implementation

* Comparison of rule with AQMP or other plan commitments

* Discussion of other effects, such as water pollution, global warming gases, etc.

* Documentation and references to all studies, data, and workgroup minutes.

In addition to cost, the adopting agency must also consider the lead times that are to be imposed for rule implementation. The lead time allowed before a rule comes into effect is determined based on two criteria. First, the availability of needed technology must be considered and the time that it will require for a source to implement the technology. Second, the ability of the industry to absorb the cost of implementing the control requirements must be considered. In most locations, rules requiring basic off-the-shelf technology with costs that are small relative to the size of the operation typically expect implementation within a year or two at the most. In cases where the control technology is just being developed or becoming available and/or the costs are significant relative to the size of the regulated source, then three to ten years are allowed to implement a control regulation. Natural maintenance cycles at industrial sources can also be considered in establishing rule deadlines if it does not push the deadlines into unreasonable timeframes.